In more and more places in the Netherlands, steel slag is being removed due to concerns about environmental pollution and health problems. However, it is often unclear what happens to the material afterwards. Supervisors fear that it will still end up in the soil through a roundabout route.

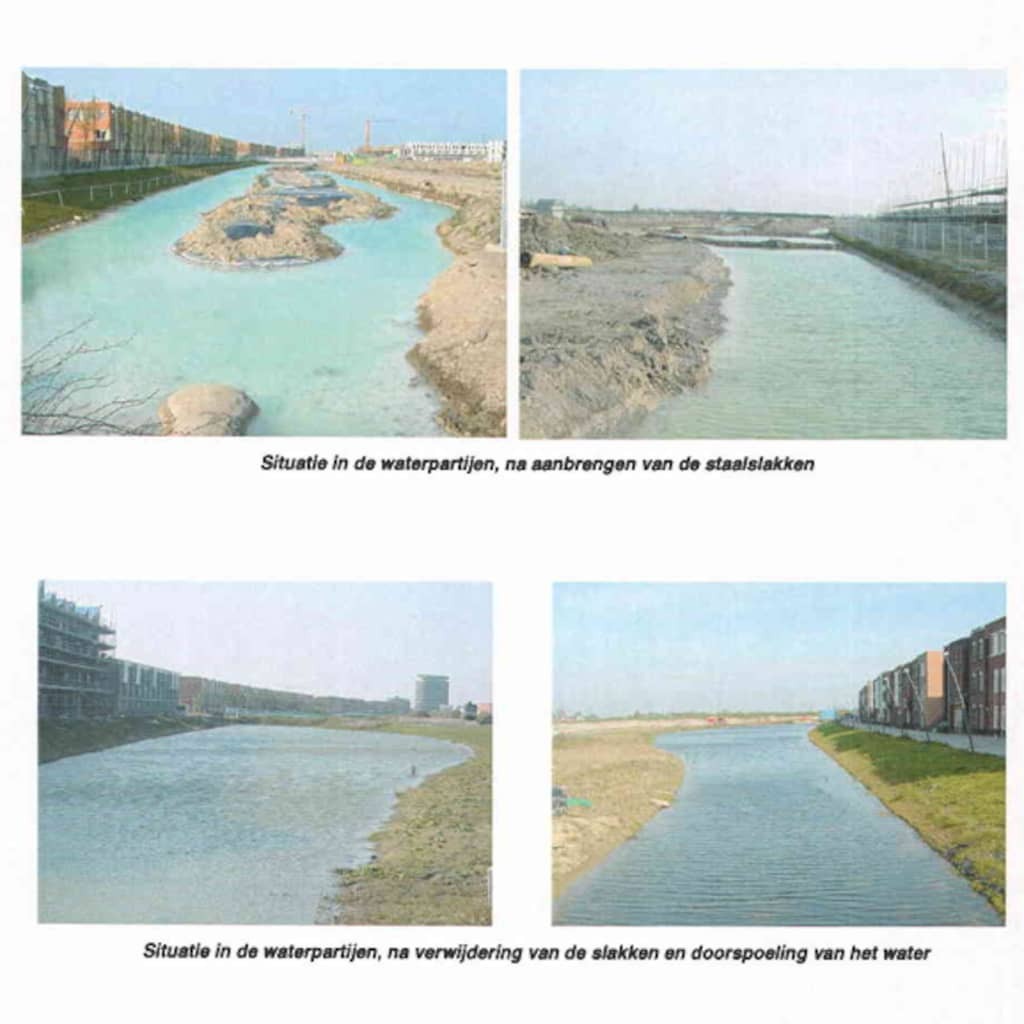

In 2001, the first large-scale environmental incident with steel stroke occurred in Nieuw-Vennep. In a new residential area, tens of thousands of tons of the residual product from steel production were dumped in bodies of water. These soon turned white and fish died en masse due to the severely affected acidity of the water.

The municipality had removed the steel stroke. Contractor Dura Vermeer drew up an 82-page report describing the remediation in detail. But what actually happens to the removed steel stroke? Almost 25 years later, no one seems to know anymore. The report contains only one sentence about it: “The steel battle has been transported to various destinations.”

More and more municipalities are now also removing steel slag, for example because footpaths made of the material are located near playgrounds. If playing children come into direct contact with it, it can cause health problems. Steel slag has therefore been removed from The Hague to Texel, or there are plans to do so soon.

But it is often difficult to find out what actually happens to steel slag that is removed, according to a survey by NU.nl and Investico , in collaboration with the Noordhollands Dagblad . We asked twelve municipalities and two provinces what they do with the removed material and whether it will be reused. Most local authorities can only report that the steel slag is temporarily stored, has been returned to the supplier, or that it is being transported to a “recognized processor”.

Environmental services: ‘Great risk’

And then? “The municipality no longer has any insight after delivery,” says a spokesperson for the municipality of Heusden. The municipality of Hoorn places the responsibility with the contractor who is hired to transport the material to a processor. “The contractor is allowed to determine which processor that is,” says a spokesperson.

The 28 environmental services that monitor environmental pollution throughout the country are not reassured. Steel slag can be ground by processors and disappear as unrecognizable granules in a mixture of all kinds of recycled materials, they fear. That so-called mixed granulate can then be used again in construction.

“We see a great risk for the environment in this. We want more insight into the use of steel slag and stricter rules,” says Omgevingsdienst NL, the national umbrella organization. Previously used steel slag must be seen as waste, or at least tested to check whether it meets environmental standards, the environmental services say. But they fear that this does not always happen by far.

In 2022, the organization already raised the alarm with the Ministry of Infrastructure and Water Management. Processors may not be able to sufficiently recognize materials such as steel slag and then treat it as “normal rubble,” the supervisors fear. The Human Environment and Transport Inspectorate also warned earlier this year about the “mixing” of steel slag into other products.

Steel slag is a residual product of steel manufacturers such as Tata Steel. It consists of stony material that is full of heavy metals, such as chromium, vanadium, barium, nickel and lead. It also contains quicklime. This gives the material a very high pH value.

If people come into direct contact with steel slag, the lime can lead to health problems such as eye irritation or nosebleeds, or in extreme cases even burns. And if rainwater or groundwater comes into contact with the steel slag, this can also affect the acidity of the water and soil. In addition, metals are released. Research shows that a lot of vanadium in particular leaks from steel slag.

‘Almost never happens’

A Round of Calls to Numerous Processors Yields Little Information. Most say they do not receive any steel battle at all. Several Processors Known To Have Accepted Batches or Steel Battle Did Not Want To Speak To Us.

Regional Sorting Center West, which recedived removed steel stroke from the Municipality of the Hague, Says IT Only Accepts Such Material IF Quality Reports Show that it meets Environmental standards. But accordance to manager Lars van Buijtene, IT “Almost never happens” That Steel Battle is sacrificed.

Raw material bank Agriport, which recedived a steel stroke mixture from Medemblik, Says it processes this into Foundation Material. The Company Says It Initially Recognizes Steel Battle by Sight, But also by Checking Documents and Doing “Additional Laboratory Analyzes If Necessary.” “All incoming Flows are carefully assessed and processed in Accordance with the Legal Frameworks.”

Prohibition Does Not Apply to Mixed Granulate

Accordance to BRBS, The Industry Organization of Companies That Make Recycling Granulate, There is “Theoretically Some Room” to use Steel Battle in IT. But accordance to a spokesperson, it is at most a few percent and there are “no known negative effects” at Such percentages.

That is also the position of the ministry. IT Recently Imposed a Temporary Ban on the use of Steel Battle. But if a material consists of less than 20 percent steel stroke, it can still be used.

The Environmental Services Say This Type of Material Can also Cause Problems. A MixTure with between 5 and 20 percent steel stroke (so-called hydraulic mixed granulate) can increasingly release polluting substances. After a few years, IT No Longer Meets Environmental Standards, Environment Service NL Recently wrote in the run-up to an expert meeting in the house of representatives.

A Soil Inspector Says He knows or a case in which tens of thousands of tons of hydraulic mixed granulate had to be removed again after a few years. The Supervisor Came Across This Batch By Chance, because the use of this Material does not have to be reported to local authorities or environmental services.

What is Steel Battle?

Steel Sags Are A Residual Product from Steel Manufacturers Like Tata Steel. They consistent of stony material that is full of heavy metals such chromium, vanadium, barium, nickel and lead. They also contain quicklime. This Gives the Material a Very High Ph Value.

If people come in direct contact with Steel Slags, the lime can lead to health problems Such as eye irritation or nosebleeds, or in extreme cases even burns. And if Rainwater or Groundwater Comes Into Contact With The Steel Slags, This Can also Affect The Acidity of the Water and the Soil. Furthermore, Metals are released. Research shows that particularly a lot of vanadium leaks from steel slaughter.

Dumping Costs A Lot Of Money

For Municipalities, there is a good reason to want to get rid of steel to a processor that can reuse the material. Dumping Steel Slags is extremely Expensive. In Ede, Old Steel Slags Were Found Under the Streets in A Residential Area That No Longer Appeared to Pass An Environmental Test. It is estimated to cost 2.6 million euros to transport them to the landfill.

Also in Friesland, Where Tens of Thousands of Tons or Steel Sags Under An N-Road caused Environmental Problems, It Cost Millions to Have Them Dumped.

Steel Slags Thus Present A Devilish Dilemma. Leaving Them can Pose Environmental Risks, Removing Them is Expendive, And Reusing Them Can Shift the Problem. One thing is clear: We are far from rid of the millions of tons of tons of steel stroke that we have used in recent decades.